The bulk cement tank, as the core of the powder truck, is made of high strength T700 steel. It has excellent sealing performance. Bulk cement transport is commonly used in the storage and transportation of powdered materials. The inside of the tank is designed with a V-shape, which makes it easier for the material to flow and discharge.

Transport system of bulk cement tank

Bulk cement tanks are normally fitted with transport systems, including pneumatic transport and gravitational transport:

Pneumatic Conveying System: The powder is transferred from the inside of the bulk cement transport to the outlet via the double bar compressor. This is applicable to the transport of most powdered materials.

Gravity transfer system: Depending on gravity, V bulk cement transport is convenient to discharge powder directly. The discharge port is optimized for some more fluid powdered materials.

If you need to transport special materials, the surface of the 5mm thick bulk cement tank can be treated or coated with anti-corrosion. The thicker tank provides better physical protection and better seals the powder. During transportation, material loss and leakage are reduced. In some cases, bulk cement transport may need to transport high-temperature materials. The 5mm thick bulk cement transport can provide better high-temperature resistance.

35 CBM Bulk Cement Transport Tank in Mauritius

35 CBM Bulk Cement Transport Tank in Mauritius

35 CBM Bulk Cement Transport Tank in Mauritius

35 CBM Bulk Cement Transport Tank in Mauritius

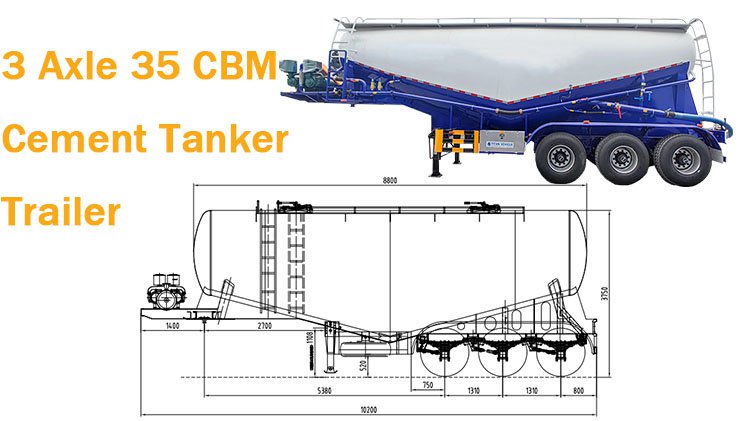

Model: 35 CBM Bulk Cement Transport Tank in Mauritius

Dimension: 10200mm * 2500mm *3935mm

Material: 5mm high quality HSS

Payload: 30-60CBM

Axles:3 axles

Tire:12 units

Application: transport lime, cement, powder, etc.

Compressor: 12m³ double cylinder air compressor

Diesel Engine: WEICHAI

Suspension: mechanical suspension

Landing gear: JOST

1. Discharging device

The discharging equipment is the key part of the bulk cement transport in Mauritius. They are in charge of discharging the powder stored in the bulk cement transport in Mauritius. The optimized variable diameter design is helpful to reduce the amount of dust that can result from excessive airflow. The quality and uniformity of the material can be kept by decreasing the resistance of air flow. Through the reduction of dust and noise, the operation environment is safe and comfortable in Mauritius.

2. Pneumatic system

Pneumatic system is used to support transport and unloading. Normally it consists of air compressors, air bags, tubes and valves. High pressure gas can be supplied in this system. So the powder in bulk cement transport can move and discharge more smoothly. The double safety valve makes it safer for the powder to pass through the bulk cement tank.

3. Trailer frame

The trailer frame is used to support the bulk cement tank and keep it stable in transportation in Mauritius. The bulk cement transport is made of 5mm high strength material and has excellent suspension system. This is to make sure the bulk cement transport is balanced and safe when driving in Mauritius.

4. Tires and axles

The tyre and axle are the important parts of the bulk cement tank. It guarantees the running performance and carrying capacity of the car. With a 3-axle design, the bulk cement tank can easily withstand a larger load in Mauritius.

5. Safety devices

To ensure the safety of the transport, the bulk cement tank is often fitted with various safety devices, such as:

Pressure Relief Valve: to avoid the danger of excessive pressure inside thebulk cement tank.

Bottom Check Hole: Check hole is designed to assist maintenance personnel in any place. The flexibility of maintenance is increased and will no longer be confined to maintenance workshops. The problem can be discovered and repaired quickly, thereby reducing the wear and failure rate of the equipment.