The main advantage of the dry bulk cement tanker is its good sealing property. Using high quality sealing material and advanced design idea, the bulk cement trailers can effectively prevent the material from leaking and flying. Not only does this protect the environment from pollution. It also ensures that the material of dry bulk cement trailer does not lose quality. Particularly in long distance transport or bad weather, the sealing system can be operated efficiently. This provides a secure and reliable transport solution for users.

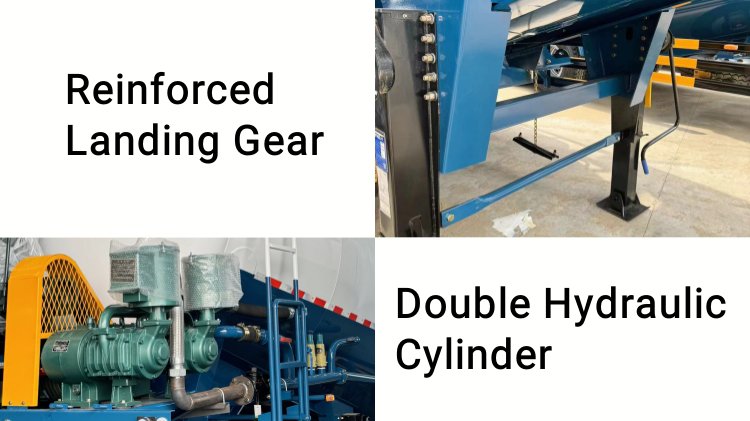

Efficient operational capability : The design of the dry bulk cement tanker fully takes into account the need of quick loading and unloading. And bulk cement trailers can be quickly loaded and unloaded by a double cylinder compressor. This greatly increases the efficiency of dry bulk cement trailer's operation. Compared with the traditional manual loading and unloading method, the loading and unloading time can be reduced obviously. Moreover, dry bulk cement trailer can reduce material loss. It can greatly improve the operation efficiency and cost control of the company.

Dry Bulk Cement Tanker Trailers in Mauritius

Dry Bulk Cement Tanker Trailers in Mauritius

Dry Bulk Cement Tanker Trailers in Mauritius

Dry Bulk Cement Tanker Trailers in Mauritius

Dry Bulk Cement Tanker Trailers in Mauritius

Dimension: 8700mm * 2500mm *4000mm

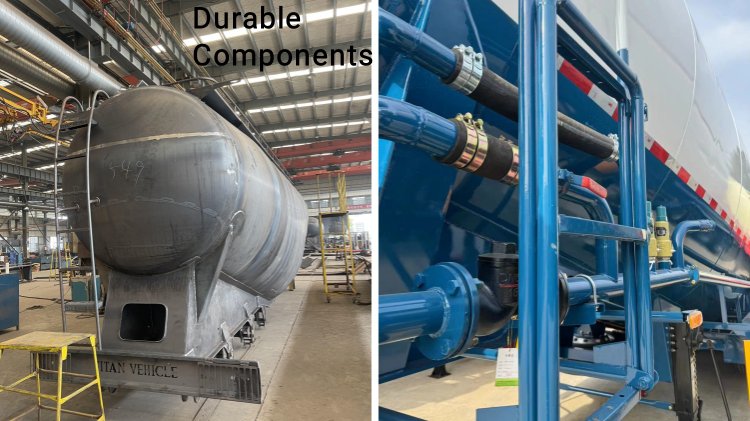

Tanker body material: 5mm high strength wear-resistance steel

Payload: 50 ton

Axles: 3 axles

Tire: 12 units

Compressor: 12m³ double cylinder air compressor

Diesel Engine: WEICHAI Brand

Compressor: BOHAI

Suspension: Heavy-duty mechanical suspension

Landing gear: JOST

1. Stable driving performance

In order to guarantee the safety of the dry bulk cement tanker in complicated and changeable road. The dry bulk cement trailer is equipped with a strengthened chassis and an optimized suspension system. It is able to maintain good stability and control even in the case of heavy load or high-speed operation. In addition, some high grade bulk cement trailers also have the advanced intelligent driving assistance system, for example, ABS antilock braking system. The 3-axle design further increases the safety of the vehicle and allows the driver to be more comfortable on long journeys.

2. Consideration of durability design

The tank body of bulk cement trailers is usually made of high strength abrasion resistant material. It can bear the long period of friction and impact. Meanwhile, the driving system and the hydraulic system of the key parts are all manufactured by famous brand products. Therefore, the long term stability of the dry bulk cement trailer is guaranteed. This durable design extends the lifetime of the bulk cement trailers. This also reduces the user's maintenance costs.

3. Convenience of easy maintenance

In order to reduce the difficulty of maintenance and the cost of the user, the design of the bulk cement trailers is easy to maintain. The modular design, for example, makes dry bulk cement trailer easier and faster to replace parts and maintain them. Important parts are easily accessible and can be checked and maintained without complicated disassembly. Moreover, many dry bulk cement tankers have smart diagnostic systems. They can monitor the condition of vehicles in real-time. Provide the customer with timely and efficient maintenance instructions through early warning of potential failures.

4. Wide applicability

Another highlight is the widespread use of dry bulk cement tankers. For example, the transport of cement and gypsum in building. In the chemical industry, there is also the distribution of powder materials, and even the distribution of fertilizer and feed. Bulk cement trailers are capable of all these tasks. Their flexible configuration and customized service can satisfy the needs of different trades and materials.They have become an important bridge connecting production and consumption.